Blog

- 2024-11-18

Information Of Logistics Exhibition In May, 2021

Munich Transport Logistics Exhibition, Germany Time: 04/05/2021-06/05/2021 Address: Euro-German Munich New International Expo Centre Organizer: Munich Exhibition Company, Germany Munich Transportation Logistics Exhibition (Transport Logistic) is the largest exhibition in the global logistics industry. Participation in the exhibition will help to improve the scope of the exhibition, especially for the storage equipment production industry. Scale: total area of 115000 square meters ,2162 exhibitors enterprise ,60726 exhibitors. German Bremen Transport Logistics Warehousing ExhibitionTime: 17/05/2021-19/05/2021 Address: German Bremen Convention and Exhibition Center Organizer: UK Exhibition Group German Bremen Transportation

Potential Safety Hazard Of Warehouse Racks

As the professional logistics using facilities, warehouse racks are widely applied in many industries such as logistics, factories, enterprises, warehouses and business users, etc. Therefore, the safety of racking system is of vital importance. There are many different kinds of warehouse racks, many users when buying them don’t know how to evaluate the quality of warehouse racks and choosing the right ones, so often decides by price, finally they find that racks are not applicable for their warehouse or poor quality. In this case, the users should

How To Judge The Quality Of Steel Racking

First, the source of steel High-quality racking suppliers will use Baosteel Q235 rolled steel or similar high-quality steel, while poor suppliers often offer low-quality steel from smaller mills. It is suggested that users can judge by the following methods: 1.Please ask the supplier to provide the corresponding steel warranty, and confirm whether the supplier purchases this batch of materials through the telephone number on the warranty 2. Entrust authoritative testing institutions to test the mechanical properties of steel. Generally speaking, the yield strength of high-quality Q235

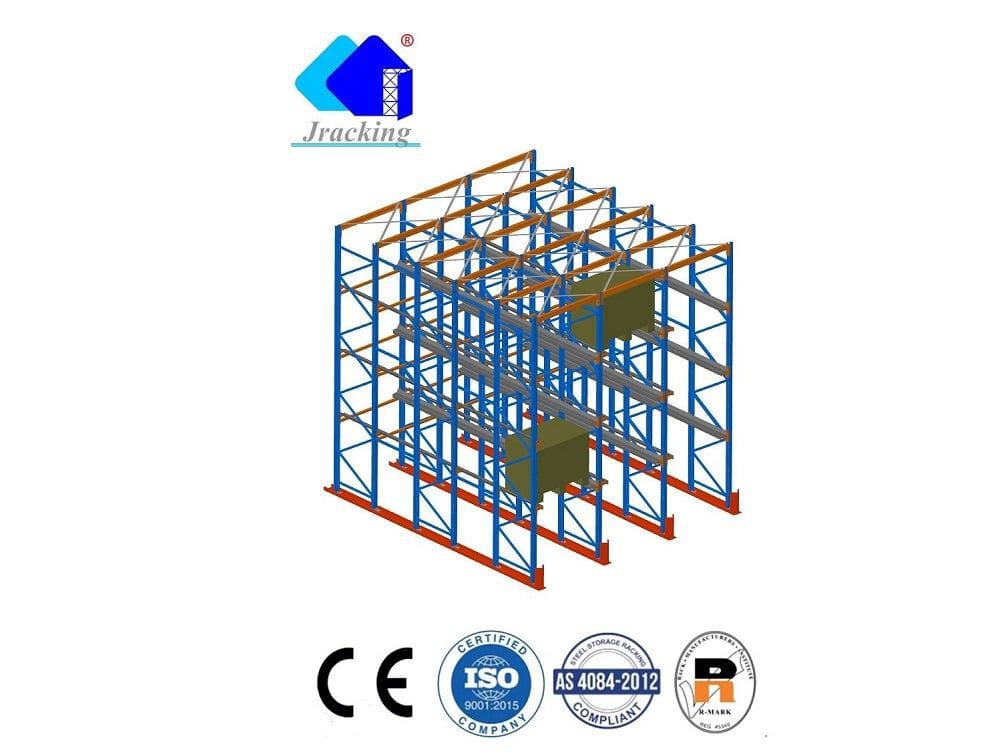

Warehouse Pallet Racking

Warehouse Pallet Racking Pallet racking has been used for the last 50 years to maximize warehouse storage. There are many types of pallet shelves. Pallet racking should be designed to fit the required product volume and handle the required throughput. Many pallet racking systems are poorly planned, resulting in aisles taking up a large amount of warehouse space. The racking system must be used with the correct type of forklift to maximize efficiency examples of racking systems Single Deep Selective Pallet Racking Each and every pallet is

Project Case -shuttle Racking System In Brisbane

Shuttle Racking System in Brisbane Industry & Goods Category: Food Storage: 294 pallets location Area: 163 square meters Equipment: 2 shuttles, 2 spare batteries, 1 charging cabinet Meet customer’s needs The first quotation of this project was made in March 2017, and the customer chose gravity rack system solution. Due to the complex storage environment and the products, our solution was modified for 11 times. After 7 months, some problems still arose and the client wanted to redesign the project from a gravity rack system to a shuttle racking system, we redesigned. The project

Project Case-shuttle Racking System Of Company B In Syney

Project Case – Shuttle Racking System Company B In Sydney Industry & Goods Category: Food& milk powder Storage: 24 pallets wide x 10 pallets deep x 4 pallets high =960 pallets location Equipment: 3 shuttle cars, 1 spare battery Meet customer needs First of all, company B wanted to increase the storage density, so our solution was up to 24 pallets in depth. Secondly, due to the frequent storage of goods, we equipped three shuttles for the system. Finally, the whole project was successfully installed. Our solution achieves both